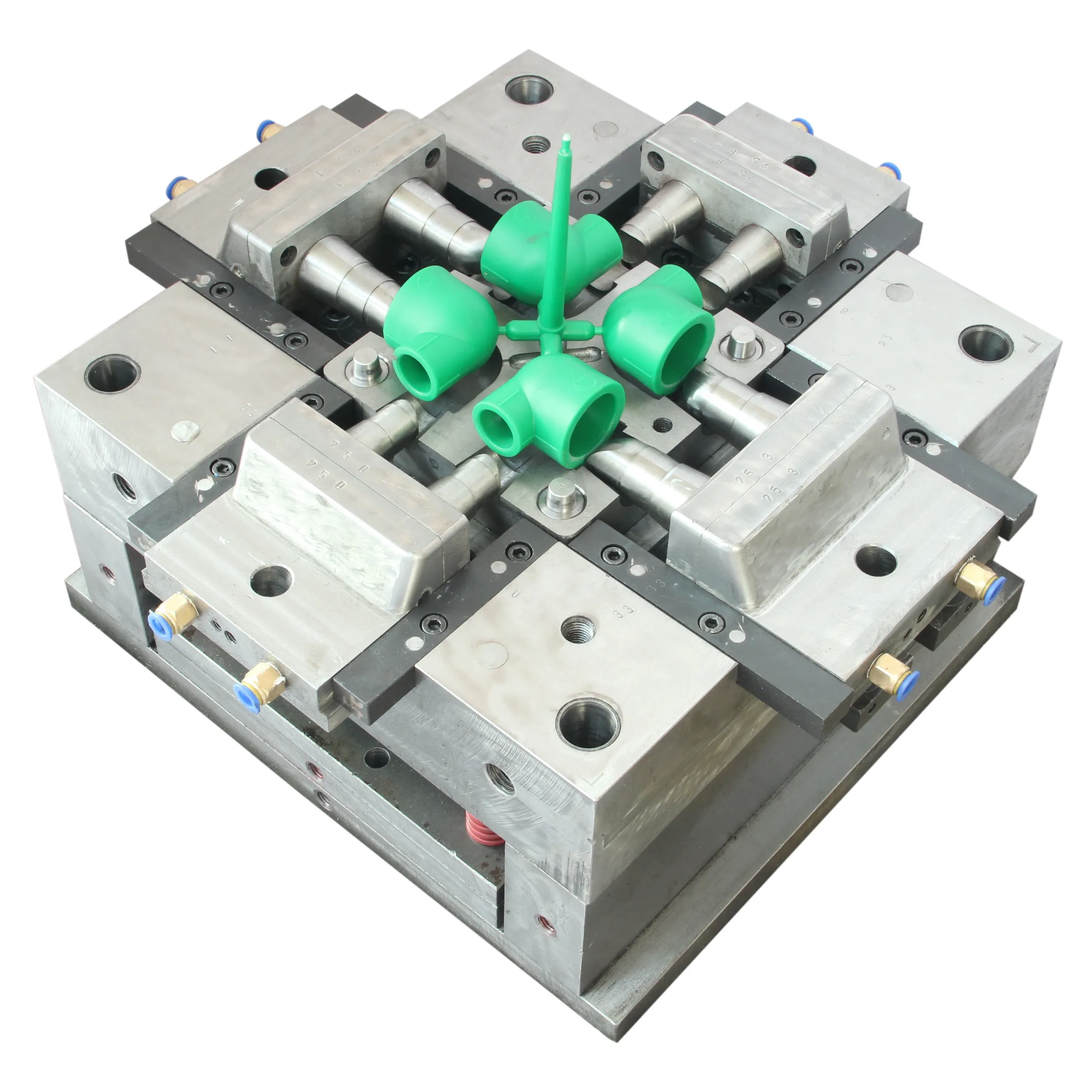

PP-R90度弯头模具

PP-R 90-Degree Elbow Mold: Design and Functionality A PP-R 90-degree elbow mold is a precision tool used in the injection molding process to manufacture polypropylene random copolymer (PP-R) pipe fittings, specifically 90-degree elbows. These fittings are essential in plumbing and HVAC systems, enabling smooth directional changes in piping networks while maintaining flow efficiency and pressure resistance. The mold’s design and construction play a critical role in ensuring the quality, durability, and dimensional accuracy of the final product. Key Features of the PP-R 90-Degree Elbow Mold 1. Material and Durability The mold is typically made from high-grade tool steel, such as P20, H13, or stainless steel, to withstand high injection pressures and prolonged use. Hardened steel components enhance wear resistance, ensuring a long service life even under continuous production cycles. 2. Precision Engineering The mold cavity and core are CNC-machined to exact specifications, guaranteeing tight tolerances (typically within ±0.02mm) for consistent fitting dimensions. The 90-degree bend angle must be precisely maintained to ensure proper alignment when installed in piping systems. 3. Cooling System Design Efficient cooling channels are integrated into the mold to regulate temperature during the injection process. Uniform cooling minimizes warping and internal stresses in the PP-R elbow, improving product consistency and reducing cycle times. 4. Ejection Mechanism The mold incorporates ejector pins or sleeves to smoothly release the molded elbow without deformation. Proper ejection design prevents surface defects and ensures smooth demolding, even for thicker-walled fittings. 5. Surface Finish The cavity and core surfaces are polished or textured to achieve the desired finish on the PP-R elbow. A smooth interior surface reduces friction in fluid flow, while a matte exterior may be preferred for handling and aesthetics. Production Process The PP-R material is heated to a molten state and injected into the mold under high pressure. After filling the cavity, the material cools and solidifies into the elbow shape. The mold then opens, and the finished fitting is ejected. Post-processing, such as deburring or quality inspection, may follow. Applications PP-R 90-degree elbows are widely used in hot and cold water systems, industrial pipelines, and chemical transport due to their corrosion resistance, thermal stability, and leak-proof joints. The mold must produce fittings that meet international standards (e.g., ISO 15874, DIN 8077). Conclusion A well-designed PP-R 90-degree elbow mold ensures high productivity, dimensional accuracy, and long-term reliability of the fittings. Its robust construction, precision engineering, and efficient cooling system contribute to cost-effective manufacturing while maintaining the high performance expected in modern piping systems.

产品

分类:

-

PP折叠弯头管件模具

所属分类: PP管件模具浏览次数: 605编号:发布时间: 2025-09-16 23:46:09PP折叠弯头管件模具产品名称:PP可折叠弯头90°管件模具腔数:16腔材质:PP模具结构: 油缸结构型腔/型芯钢材:2738或718用于型腔和型芯型芯/型腔硬度:真空热处理后HRC 40-45度注塑机:380T Taizhou Huangyan Hongjin plastic mould一、专业从事塑料模具制造,产品包括:PPR PVC PP PE等管材模具、日用品模具、周转箱模具、塑料阀门模具、瓶子模具等2、生产能力:可根据2D图、3D图或实体样品进行模具设计、绘图和制造。3、模具材质:型腔型芯根据客户需求4、冷却系统:采用循环水,有效提高产品生产效率5、后处理:氮化(氮化处理温度低,变形小,不再需要淬火,不仅具有较高的表面硬度而且提高耐磨性)6、模具寿命:P20模具材料正常使用不得... -

40mm PPR弯头90度管件模具

所属分类: PPR管件模具浏览次数: 538编号:发布时间: 2025-10-23 18:12:1040mm PPR弯头90度管件模具模具名称:40mm PPR弯头90度管件模具腔数:2腔模具尺寸:20-50mm模具钢:型腔、型芯2738或718登机口:直接登机口模具结构:斜导柱滑块结构型芯/型腔硬度:真空热处理后HRC 32-45度注塑机:250T台州市黄岩宏进模具有限公司成立于2002年。我们专业设计和制造管件模具超过23年。我们期待与您的长期合作。以下是主要信息,供大家参考。常问问题:1.你的最小起订量是多少?1套就可以了2.你们的交货时间是多少?交货时间约为 60-75 个工作日。3.什么是装运港?MOLD船到宁波或上海港都可以。4.你们的付款条件是什么?我们接受提前 40% T/T,发货前余款 60% TT5.我该如何联系您?您可以通过电子邮件、whatsapp 或微信联系我那么...

新闻

分类:

-

[Company News]Customer Photo

2025-12-09 21:33:14

案例

分类:

视频

分类:

暂无搜索结果!

下载

分类:

暂无搜索结果!

招聘

分类:

暂无搜索结果!

推荐产品

暂无搜索结果!

Whatsapp

Whatsapp 电话

电话