供水管道部件模具

Mold for Water Supply Piping Components Molds for water supply piping components are critical tools in the manufacturing of plumbing systems, ensuring the production of high-quality, durable, and leak-proof parts. These molds are designed to create components such as fittings, valves, connectors, and joints, which are essential for efficient water distribution in residential, commercial, and industrial applications. Material and Design Considerations The molds are typically made from high-grade steel or aluminum to withstand high pressure and temperature during the injection molding process. The choice of material depends on factors like production volume, component complexity, and cost efficiency. Steel molds offer superior durability for large-scale production, while aluminum molds are lighter and more cost-effective for prototyping or smaller batches. Precision is paramount in mold design to ensure dimensional accuracy and smooth surface finishes. Advanced CAD/CAM software is used to create detailed 3D models, optimizing the mold for manufacturability. Features like cooling channels, ejector pins, and venting systems are integrated to enhance cycle times and minimize defects such as warping or air traps. Manufacturing Process Injection molding is the most common method for producing plastic piping components. Thermoplastics like PVC, CPVC, PEX, and PP are melted and injected into the mold cavity under high pressure. The material cools and solidifies, taking the shape of the mold before being ejected. For metal components, die-casting or forging may be used, requiring molds with higher heat resistance. Quality and Performance The mold must produce parts that meet stringent industry standards for pressure resistance, corrosion resistance, and longevity. Tight tolerances ensure proper sealing and compatibility with other piping systems. Post-molding processes, such as deburring or surface treatment, may be applied to enhance functionality. Innovation and Sustainability Modern molds incorporate innovations like multi-cavity designs to increase production efficiency and reduce material waste. Sustainable practices, such as using recycled plastics or energy-efficient molding machines, are also gaining traction. In summary, molds for water supply piping components play a vital role in delivering reliable, efficient, and safe plumbing solutions. Their design, material selection, and manufacturing precision directly impact the performance and longevity of the final products.

产品

分类:

-

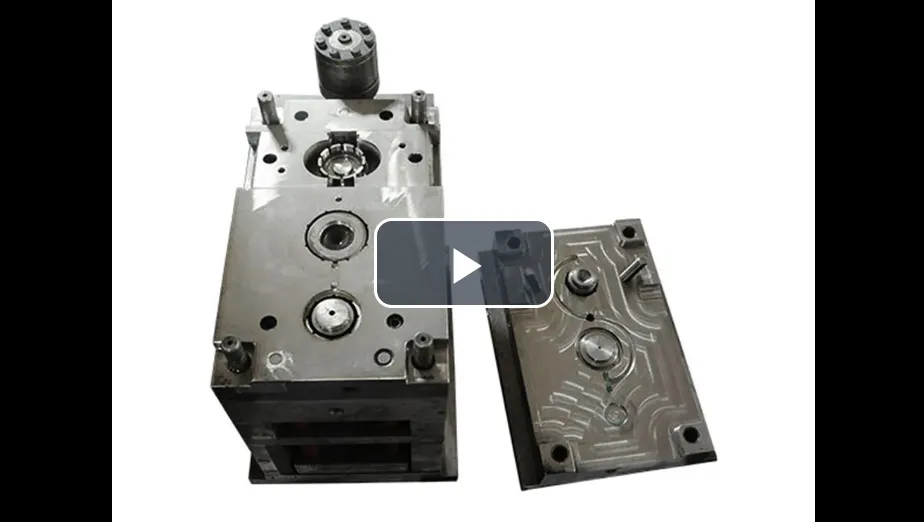

PVC阀门手柄管件模具

所属分类: 球阀管件模具浏览次数: 578编号:发布时间: 2025-09-17 00:24:22PVC阀门手柄管件模具模具名称:PVC阀门手柄管件模具腔体:8 个腔体模具尺寸:50mm模具钢:型腔、型芯2738或718登机口:直接登机口模具结构:顶杆凸出型芯/型腔硬度:真空热处理后HRC 38-42°注塑机:180T 台州市黄岩宏进模具有限公司成立于2002年。我们专业设计和制造管件模具超过23年。我们期待与您的长期合作。以下是主要信息,供大家参考。常问问题:1.你的最小起订量是多少?1套就可以了2.你们的交货时间是多少?交货时间约为 60-75 个工作日。3.什么是装运港?MOLD船到宁波或上海港都可以。4.你们的付款条件是什么?我们接受提前 40% T/T,发货前余款 60% TT5.我该如何联系您?您可以通过电子邮件、whatsapp 或微信联系我

新闻

分类:

-

[industry news]注塑模具加工过程中受以下因素影响

2024-09-06 16:57:27

案例

分类:

视频

分类:

下载

分类:

暂无搜索结果!

招聘

分类:

暂无搜索结果!

推荐产品

暂无搜索结果!

Whatsapp

Whatsapp 电话

电话